Full service isn’t what it used to be. Today the model has evolved into a low labor, high production process due to new technologies which are available. These include belt conveyors and automated point of sale equipment, and with an express detail-only operation, the technology can reduce labor even more and make interior cleaning an extremely profitable service.

Belt conveyors

A belt conveyor system for interior cleaning has allowed many operators to process an enormous amount of volume. The system works much like an assembly line and manages flow rate at a consistent pace. This increased process speed increases efficiency and can greatly reduce labor, thereby saving you money. It also can increase the average ticket price because you can offer higher dollar services on a belt at a faster pace.

Ryan Magazzine of Station Auto Wash of Leesburg, VA, has a single 165-foot tunnel, and three 75’ interior belt conveyors. Magazzine averages an overall $24 ticket. “We have the ability to run different process speeds on each belt for different services,” Magazzine explained. “On our high-dollar slower belt we do spray waxes. Our top package is $43 and is processed in just 20 minutes. The belts also give a great impression to the customer that we are a professional and cutting edge operation.”

Automated pay stations

Automated pay stations are widely used in the carwash industry for express exterior sites. Flex-serve operators know that auto tellers generally outsell human ticket writers, but often miss the point that the same technology can be applied to hand-finished service sales.

A second screen page on the auto teller allows customers to select interior services as well as their exterior preferences. This, along with stack control and self loading, creates a smooth and seamless process for the customer using a minimal labor environment. With a single or no employee at the tunnel entrance, labor is concentrated in the hand-finished service area where it adds the greatest value.

“The real value of this technology goes well beyond speed of service,” according to Kevin Detrick, president of Innovative Control Systems of Wind Gap, PA, which provides Windows-based software for point-of-sale and management systems for the carwash and detailing industry. “A consistent greeting and attractive graphics also add to the positive customer experience. Creative use of video and branding imagery also helps deliver your value message quickly and effectively. The result is greater customer satisfaction and loyalty.”

Express detailing only

Some operators have decided if they are going to go into interior cleaning, it better be worth their effort.

Let’s, for example, use a flex model along with a belt conveyor, which also requires a high ticket to have any interior services done. This will now make the site into an express plus detailing model where you again minimize labor, usually needing only four to eight employees, and now have about a $30 base price to have any interior services done. If your site model offers interior services, it’s worth your effort to provide belt conveyors because you will maintain a low labor facility and can highlight your express washing services. This will become a more common flex serve model in the future thanks to the use of belt conveyors.

Through the use of the newest technologies, full service carwashing has transformed into a low labor, high dollar business model. The wash process has become efficient through the use of belt conveyors and process methods. As a result, we have been able to reduce more labor costs thanks to auto pay stations and self loading. With using express detailing, or high dollar service only on the detail belts, we have created an easy and profitable full serve-model to manage and operate.

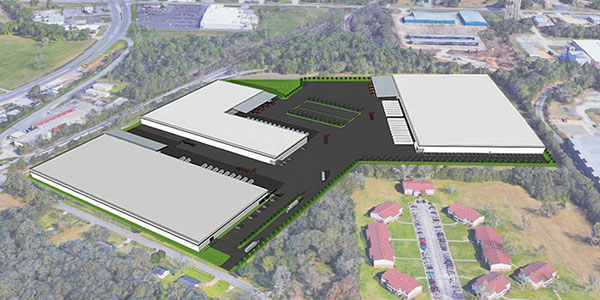

Ryan Essenburg is chief operating officer of Tommy Car Wash Systems. He has assisted in the development and construction of over 100 conveyorized carwashes.