The industry has heard customer concerns about visiting a carwash and responded with innovation and more choices over the decades to quell angst. However, at the end of the day, a customer’s desire to have a clean, dry and shiny result has not changed, regardless of wash type. And, as more new investors flood the professional carwash market, some are seeing that the science of carwashing is more than meets the eye.

No time to read this article? Listen to it instead!

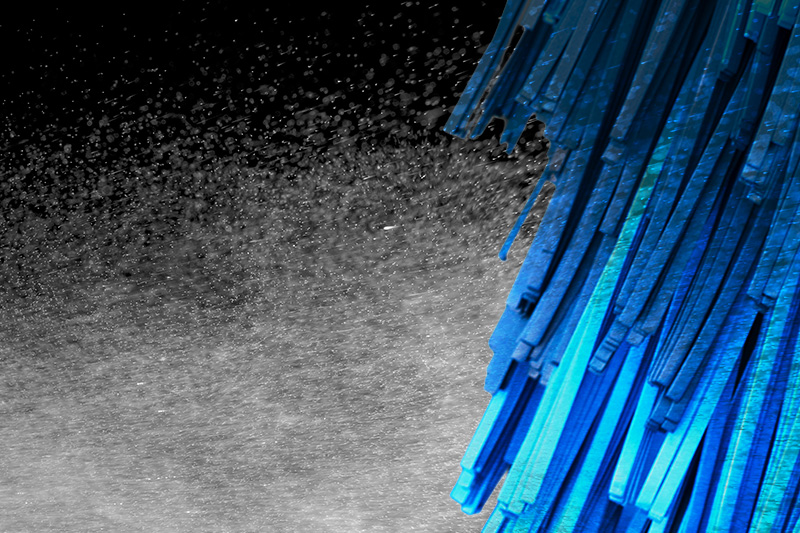

One choice both investors and customers have when it comes to carwashing is choosing a soft touch (friction) or touchless wash. But, what are some of the main differences?

We came in contact with three industry pros to discuss the chief differences in visiting and operating a soft touch versus a touchless location.

Touching on customer perceptions

A leading objective for successful operators is to make all customers feel comfortable while on-site. In order to create a welcoming environment, it’s important to understand why some customers might prefer a frictionless wash over a soft touch site, and vice versa.

According to North American Director of Sales for ISTOBAL Ian Burton, touch-free wash packages are ideal for customers who prefer an automatic wash, but have reservations about letting a machine physically touch their vehicle’s finish.

“Touch-free carwashes will also appeal to those with aftermarket accessories that make it impossible for them to go through a soft touch wash,” adds Burton.

The perceived risk of damage seems to be a prevalent concern among touchless carwashing fans. While operators of soft touch washes can educate and demonstrate the precision of their equipment and highlight the business’ safety measures as customers are in the tunnel or bay, there will always likely be a segment of customers who simply prefer the touch-free experience.

“Some customers still have the impression that the ‘brushes’ on a soft touch wash will scratch the paint. Some customers believe the brushes will rip off antennas and wipers or damage side mirrors,” notes Jerry Canfield, chief innovation officer for D&S Car Wash Supply.

Some customers avoid friction washes to mitigate perceived risk and for others it comes down to familiarity. Although the trend for new builds leans to soft touch these days, mostly credited to the explosion of the express exterior segment, some customers grew up with touch-free washing and have become accustomed to the service.

“Customers tend to pull up to the touchless bay because it is a machine that they are familiar and comfortable with,” asserts Nate Wellens, distributor sales support representative at Washworld. “They understand that all they must do is put their cars in park until the sign and/or machine instructs them to pull forward once the wash is complete.”

Wellens adds that a customer’s previous bad experience with a friction wash might also make that customer a touchless lifer.

“Friction technology has been around for a very long time, but it has not always been very great. The old technology did not provide a very consistent clean and the materials used were very rough. Between these two traits, friction machines were known to wreck most vehicles that would pull into them,” continues Wellens.

Conversely, fans of friction have their own set of reasons for shunning touchless carwashing.

“Many customers believe the ‘harsher’ chemistry used at a touchless wash will ‘etch’ their vehicle’s finish over time,” inserts Canfield. “Many customers like the ‘buffed’ shine that you can get from a soft touch wash. Additionally, some customers believe a touchless machine’s high-pressure nozzles can damage pinstriping, wraps and convertible roofs.”

Operating touch-free

While those are some of the leading reasons why a customer might select touch-free over soft touch, and vice versa, what are the key differences of these wash types for operators?

Canfield notes the primary differences in operating a touchless wash compared to soft touch are a closer focus and control in the areas of water quality, water temperature, chemical titration and dwell time. In fact, he calls upholding these areas of a frictionless wash “all absolutely vital to maintain excellent wash quality.”

What’s the recommended dwell time, chemical temperature and pressure needed at a touchless wash to fully remove road film, grime, dirt and debris? With so many variables to consider, each wash’s needs are unique. But, Canfield concisely provides a general guidance to the question: “Three-plus seconds (chemical dwell time); no more than 120 degrees F (chemical temperature); and 1,200 psi.”

While these are general recommendations, each carwash environment and locale are different so it’s best to connect with a reputable manufacturer, installer or dealer for the ideal application tips for your particular touchless site.

Without agitation from brushes, touchless washes must rely solely on the chemistry used, in combination with the right water pressure, application, quality (soft water) and temperature, to remove dirt, oil, insects and debris. This creates a smaller margin for error when compared to soft touch.

“Because of this, the chemicals needed to loosen and remove those substances for a quality wash are often harsher than what would be necessary with soft touch equipment. In addition to harsher chemicals, a touch-free wash also requires a little longer wash time and much more water since the impingement of high-pressure water is a large part of what cleans the vehicle’s surface,” explains Burton.

As for water quality, touchless operators must employ soft water with the recommended conditions to offer an effective clean.

“If you don’t have soft water, you will not clean much of anything,” notes Wellens when discussing touch-free washes. “Once you get the water chemistry correct you move on to the chemical and each chemical is going to require a different dwell time, temperature and pressure to ensure its optimum cleaning ability.”

Cost touch points

How about costs? Does a touch-free wash cost more to open and operate compared to soft touch and is there a potential to charge a premium for this less common service? Those we contacted for this article broke down some cost comparisons of operating each wash type.

When comparing operating cost differences between touchless and friction machines, Wellens believes that both types tend to even out in the long term.

“In the purchasing process, operators will see that a friction machine is going to cost more up front due to all the additional moving parts, which in turn means the maintenance expenses will be higher on a yearly basis,” says Wellens, adding operators of touch-free washes can expect higher chemical costs when compared to soft touch. “In addition to higher chemical costs and usage [with touchless] … [a typical] friction machine uses half as much water as a touchless machine.”

Investors who are interested in frictionless washes should also be aware of some other areas that will increase overall cost of ownership and operation. According to Canfield, operating costs are “significantly higher” when comparing these wash types under equivalent conditions.

“Almost all consumptions are double or more,” educates Canfield. “It’s twice the water, three times the electricity, twice the chemical and twice the gas for hot water when operating a touchless wash compared to soft touch.”

However, as mentioned, operators can expect higher routine and preventive maintenance costs with a soft touch operation. For example, brushes, as noted, are a critical piece of equipment in friction washes. Expect to replace brush materials every 80,000 washes, logs Canfield.

In general, the experts note that the touchless carwashing equipment will be easier as well as cheaper to maintain over time. With fewer components and mechanisms involved, a touchless machine, notes Wellens, has significantly fewer moving parts that require attention and maintenance over the course of its useful lifespan.

Cost per vehicle is something seasoned operators and smart investors keep an eye on, even as membership rates grow to new heights each day. So, while customers might prefer the touch-free experience at a reasonable price, interested investors should know that Burton’s per vehicle cost comparison is not slight.

“In general, touch-free systems cost approximately 50% to 70% more per vehicle to operate than soft touch equipment,” states Burton.

Additionally, when it comes to throughput potential, soft touch seems to have the edge here as well. “A soft touch machine will wash faster than a touch-free option, allowing a site to wash more cars per hour,” continues Burton.

Best of both wash worlds

For investors and operators who are still on the fence between soft touch and touchless carwashing, consider that there are two other options: installing hybrid equipment and offering both wash types in separate bays at a single location. After all, carwashing is a service business so it’s best to let customers have it their way, which is great news for both wash types.

“For operators who want to appeal to both customer types, their best option is a true combination carwash that is capable of both a high quality, touch-free wash as well as a soft touch wash,” educates Burton. “This allows you to attract all customers interested in an automatic wash since you can offer them a choice. To properly utilize this, however, the right type of activation system is instrumental so that the customer can select the desired wash.”

It’s referred to as hybrid equipment — offering soft touch and touchless carwashing in one bay — and customers who select this option can have the best of both wash types during a single visit.

“This type of equipment is easy to market to customers because of its uniqueness, which is not offered at most places. Therefore, when customers learn that they decide how the vehicle is washed, they may see it as a benefit,” concurs Wellens.

Operators of hybrid equipment, Wellens continues, should be aware that the difficult issue with this type of machine is that it is generally tough to deliver a great clean with both types that it offers. “Great touchless and friction machines are designed specifically for their intended use and when you combine those two machines, you are going to be faced with giving up some cleaning ability of one or both,” he adds.

Alternatively, for in-bay automatic operators who have multiple bays on-site, offering each wash type in separate bays has proven to be an effective strategy to expand the customer base and increase market share.

“Our in-bay automatic carwash owners prefer to have two automatics — one soft touch and one touchless. Each one is optimized to clean the way they are designed to clean. These operators have the bays clearly marked and they end up with traffic anywhere between 60/40 to 40/60 (friction/touchless), depending on their customer base and preference,” concludes Canfield.

Whether you decide on touchless or soft touch, hybrid or separate, the tried-and-true hallmarks of operating a successful carwash remain the same. Customers want a friendly service, at a value price and a job well done. Thanks to scanning and mapping technology, which helps equipment and chemicals provide to-the-inch cleaning, better wash materials and chemistry, as well as advanced research, today’s operators are in a better position to reach new heights with soft touch and touchless carwashing options.