In the last 30 years, Extrutech Plastics Inc. (EPI) has grown from a single extrusion line, making vinyl window profiles and tubing for central vacuum systems, to now manufacturing plastic wall and ceiling panels, concrete forms, doors and other construction components for food processing, agricultural, carwashes and truck washes, pharmaceutical, animal health, cannabis production and many other industries throughout the U.S. and Canada.

EPI President Greg Sheehy founded Extrutech Plastics in January 1992 with his wife, Debbie, and brother, Pat. In 1999, Mike Sheehy joined the company. The business has expanded from a 4,000-square-foot leased building where the brothers ran their first line to the current 162,000-square-foot facility with 60 full-time employees working 24 hours across three shifts to run the company’s 22 extrusion lines.

“Really, the strength of the business has been the employees that have helped grow the business over the years,” Greg Sheehy says of EPI’s success over the last three decades. “We have a team effort in both production and sales, along with our office staff to help move everything along nice and smooth.”

EPI is highlighting its anniversary with a new logo celebrating its 30 years of operation on its advertising. Additionally, the company will hold festivities over the summer, such as an employee appreciation fry out, to celebrate the milestone with the entire staff.

The product

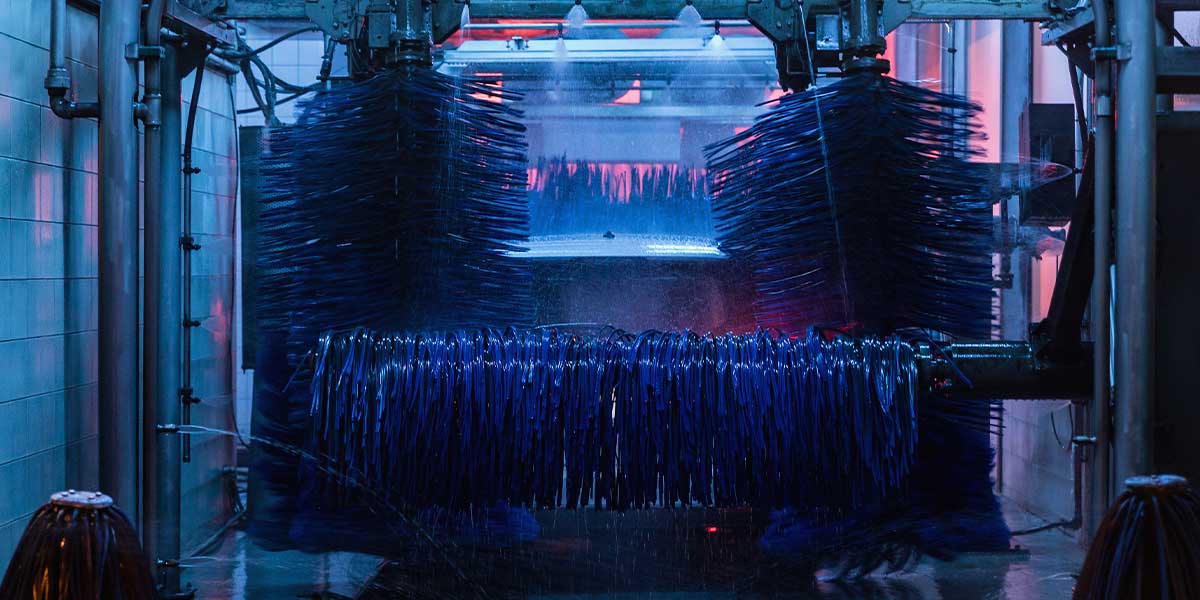

EPI has been working with the carwash industry since the mid-1990s, starting with providing its plastic liner panels for local carwashes and truck washes for walls and ceilings. As building inspectors and builders started learning about EPI’s products, the word of mouth started spreading throughout the carwash industry. “People love how easy it is to install and the shine of the finished wash bays,” Greg Sheehy says.

The addition of concrete forms for walls to EPI’s offerings in 2013 significantly expanded its ability to serve the carwash industry. In addition to the plastic wall and ceiling panels it previously provided, the concrete forms, which are 6- and 8-inch thick walls filled with rebar and concrete, provide a durable plastic surface on both sides. These stay-in-place concrete forms serve as both the inside and outside surface of a building’s walls.

“Our idea was to develop a line of construction products so a builder can come to us, and we can offer them a complete, custom package for their project,” explains Greg Sheehy. “We can supply the concrete wall forms, interior wall and ceiling panels, finish trim and doors to the customer, all from one American supplier.”

“All of our products are custom made to a builder’s or customer’s construction drawings. We will make any length, up to 20 feet, to fit their drawing, not just standard length products,” he adds. “All of our products are made in Manitowoc, Wisconsin, with all domestic compounds. Our products are ISO 9001-2015 quality certified. The products have been tested by Intertek Testing and registered with ICC-ES, a subsidiary of the International Code Council. Our wall and ceiling panels meet Class A requirements for smoke and fire. Our goal has always been to manufacture a high quality product that our customers trust and love.”

Wall panels

Extrutech’s panels are extruded from exterior grade, high quality virgin PVC and available in 12-, 16- and 24-inch widths. They can be made in white, black and primary colors to match a company’s color scheme. The Poly Board panels have a tongue and groove design with a hidden nailing fin along one side, like siding, and are designed for quick and easy installation with no exposed fasteners. They are custom cut to the desired lengths per customer’s project specifications.

“These panels would be used on the interior to cover the wall and ceiling,” Greg Sheehy notes. “We make a high quality, high gloss shiny surface, with no exposed fasteners anywhere in the carwash. They are very easy to clean, nothing wants to stick to them.”

He adds that EPI’s Poly Board panels, with their highly reflective surfaces, keep the facility’s interior bright, increasing safety and productivity, while requiring less electricity for lighting, which saves on the energy bill. Additionally, the panels are completely recyclable.

The panels include a full 20-year warranty, and Extrutech offers its customers support from the building phase and beyond. “After the sale, we will visit the job site that will be using the concrete forms, if they request assistance. We’re also available by phone or email after the project is started if there are any questions,” says Greg Sheehy. “Occasionally there might be damage at the construction site, so we are readily available to replace anything. Being here in America, it is relatively easy to resupply if there are issues at the project. The customer will not have to wait for a shipment from overseas to complete the work.”

Greg Sheehy also notes that EPI has a powerful website at www.epiplastics.com that features tons of product information and tutorial videos for customers to learn more about the company and its products.

Looking forward to the next 30 years, EPI’s president says the company wants to continue to grow and is always looking for new opportunities. “I think the carwash and truck wash industry are going to be very important for our nation and will continue to grow. As prices for new cars and trucks continue to climb, the owners will want them looking good all the time, so they will be washed more often. We hope to grow along with this industry for the next 30 years.

Since 1992, Extrutech Plastics Inc. of Manitowoc, Wisconsin, has become a world leader in the production of sanitary, easy to clean wall and ceiling panels, stay-in-place concrete wall forms, partition wall panels, doors, shutter components and many other proprietary and custom products for the construction, food processing, carwash and agricultural markets worldwide. Extrutech also services OEM customers by custom extruding profiles under contract. Please call our professional staff toll free at 888-818-0118 for assistance on your next construction or extrusion project or email us at [email protected].